Mig Wire – Stainless 309 Lsi – 0.8mm – 15KG Reel

High-performance Mig Wire 309 Lsi 0.8mm – 15KG Reel for stainless-to-mild steel welding. Clean finish, stable arc & low spatter.

- Estimated Delivery : Up to 4 business days

The Mig Wire – Stainless 309 Lsi – 0.8mm – 15KG Reel is engineered for exceptional performance when welding dissimilar metals, particularly stainless steel to mild steel. Manufactured with high silicon content (LSi), it ensures superior arc stability, reduced spatter, and excellent wetting action, resulting in cleaner welds and a polished finish. Ideal for use in construction, fabrication, automotive, food processing, and chemical industries, this wire offers optimal fusion characteristics, even in challenging applications. Whether you’re repairing stainless components or joining dissimilar materials, this 309LSi MIG wire delivers high-quality results every time. It’s vacuum-sealed for extended shelf life and consistent wire feed. Suitable for both manual and automated MIG welding processes, this 15KG reel offers excellent wire feeding with minimal downtime. Designed to work with shielding gas mixtures such as Ar+CO₂ or pure CO₂, it’s the perfect choice for professional-grade welding with precision and durability.

Key Features

High Silicon Content: Enhanced fluidity and wetting action for a clean weld bead.

Low Spatter Emission: Reduces post-weld cleanup and increases efficiency.

Dissimilar Metal Welding: Perfect for joining stainless to mild or carbon steel.

Vacuum Packaging: Maintains wire quality and prevents contamination.

Consistent Wire Feed: Smooth feeding performance for manual and robotic setups.

Detailed Specifications

Product Type: MIG Welding Wire

Material: Stainless Steel – 309 LSi

Diameter: 0.8mm

Reel Weight: 15KG

Shielding Gas: Ar+CO₂ or 100% CO₂

Welding Position: All position

Application: Stainless-to-carbon steel, stainless overlays, buffer layers

Product Benefits & Uses

Excellent corrosion resistance, even at high temperatures

Ideal for structural fabrication, food-grade equipment, and auto repair

Reduces rework due to low spatter and clean weld finishes

Compatible with most MIG welding machines

Enhances productivity in high-volume welding environments

MB15 Contact Tip 0.6mm Genuine Binzel - packet of 10

MB15 Contact Tip 0.6mm Genuine Binzel - packet of 10  1.6mm Aluminium Filler Rods (Grade 5356)

1.6mm Aluminium Filler Rods (Grade 5356)  Electrode Holder Screw Type - 600A

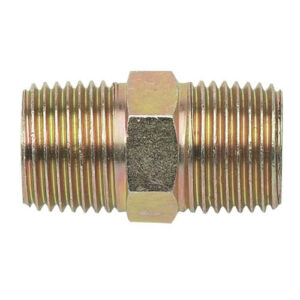

Electrode Holder Screw Type - 600A  Double Union 1/4" BSP

Double Union 1/4" BSP  Hi-Vis Two Tone Combat Trousers

Hi-Vis Two Tone Combat Trousers  CR39 Clear Lens - 5¼" x 4½" (133mm x 114mm) - Packet of 10

CR39 Clear Lens - 5¼" x 4½" (133mm x 114mm) - Packet of 10  EBP1100 1" Single Stage Electric Booster Pump

EBP1100 1" Single Stage Electric Booster Pump  BIZFLAME RAIN UNLINED - HI-VIS ANTISTATIC FR TROUSER - S780

BIZFLAME RAIN UNLINED - HI-VIS ANTISTATIC FR TROUSER - S780  1/2 BSP Male - Female PCL

1/2 BSP Male - Female PCL  R-Tech TIG Welder AC/DC 200Amp 240V with Accessory Kit

R-Tech TIG Welder AC/DC 200Amp 240V with Accessory Kit  1/4 BSP Male - Female PCL

1/4 BSP Male - Female PCL