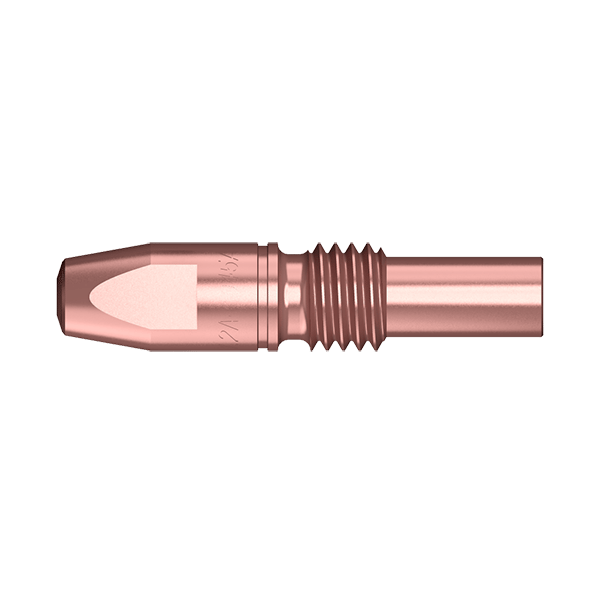

XP8 Contact Tip 5/64″ – 2.0mm (XP8-300A-450W) – Packet of 10

Durable XP8 Contact Tip 5/64″ – 2.0mm for 300A-450W torches. Delivers precision and longevity. Packet of 10 for extended welding use.

- Estimated Delivery : Up to 4 business days

The XP8 Contact Tip 5/64″ – 2.0mm (XP8-300A-450W) is engineered for precision MIG welding across industrial and fabrication environments. Designed to fit XP8 torches ranging from 300A to 450W, this tip ensures consistent current transfer, enhanced arc stability, and extended wear resistance, making it ideal for heavy-duty welding operations. Manufactured from high-conductivity materials, it provides reliable wire feeding with minimal burn back. With a standard M10 connection, installation is quick and secure. Whether you’re welding mild steel, stainless steel, or alloys, this contact tip supports optimum performance under demanding conditions. Sold in a packet of 10 , it’s perfect for workshops seeking reliable and long-lasting welding accessories. The 2.0mm internal bore size is ideal for heavier wire sizes, delivering efficient current flow and superior welding control. Backed by trusted XP8 quality, this contact tip maximizes operational efficiency and reduces downtime. A must-have consumable for professional welders.

Key Features

High Conductivity: Maintains a stable and consistent arc.

Precision Machined: Ensures smooth and accurate wire feeding.

Heavy-Duty Performance: Suitable for demanding MIG welding jobs.

Secure Fit: Standard M10 thread fits XP8-300A to XP8-450W torches.

Multipack Value: Packet of 10 for cost-effective replenishment.

Detailed Specifications

Product Code: 2308

Tip Size: 5/64″ – 2.0mm

Compatible Torch Models: XP8-300A / XP8-350A / XP8-400A / XP8-450W

Thread Type: M10

Material: High-conductivity copper alloy

Pack Quantity: 10 pieces

Product Benefits and Uses

Ideal for use with thicker wires in industrial MIG welding.

Reduces burnback and tip wear, increasing welding uptime.

Improves wire feed efficiency and current delivery.

Essential for high-amperage applications in steel fabrication.

Trusted by professionals for consistent weld quality.