Mig Wire – Stainless 316 Lsi – 0.6mm – 0.7KG Reel

High-performance 316 LSi Mig Wire 0.6mm – 0.7KG reel. Delivers precision, corrosion resistance & clean welds for stainless steel fabrication.

- Estimated Delivery : Up to 4 business days

The Mig Wire – Stainless 316 LSi – 0.6mm – 0.7KG Reel is engineered for superior performance in stainless steel welding applications. Manufactured with low carbon (316L) and enhanced silicon (Si) content, this wire delivers outstanding corrosion resistance and smooth weld beads with minimal spatter. Ideal for TIG/MIG welding of molybdenum-bearing austenitic stainless steels like 316 and 316L, it offers excellent arc stability and low fume emissions—making it a go-to choice for food processing equipment, marine structures, chemical tanks, and architectural fabrications. This 0.7KG reel of 0.6mm diameter wire is perfect for precision work on thinner gauge materials, ensuring clean, high-integrity welds. Designed to meet the rigorous demands of professionals, this stainless Mig wire supports consistent feedability and is compatible with all standard MIG welding machines. When performance and reliability matter most, choose this high-quality 316 LSi wire for unbeatable welding results.

Key Features

Enhanced corrosion resistance: Ideal for marine and chemical use.

High silicon content: Provides smooth, flat welds.

Low spatter design: Cleaner work and minimal post-weld cleanup.

Excellent arc stability: Ensures uniform bead appearance.

Precision wire feed: Smooth feeding for consistent results.

Detailed Specifications

Material: Stainless Steel 316 LSi

Wire Diameter: 0.6mm

Reel Weight: 0.7KG

Welding Process: MIG (GMAW)

Standard Compliance: AWS A5.9 ER316LSi

Shielding Gas: Argon/CO₂ Mix or Argon-rich gas

Tensile Strength: > 550 MPa

Application: Austenitic stainless steel welding

Product Benefits and Uses

Perfect for food-grade fabrication and sanitary equipment.

Resists pitting and corrosion in harsh environments.

Excellent for pipe welding, tanks, and offshore structures.

Smooth weld flow minimizes grinding and finishing.

Suited for professional and industrial-grade MIG welders.

2.4mm 2% Thoriated Tungsten (Packet of 10)

2.4mm 2% Thoriated Tungsten (Packet of 10)  MB15 Contact Tip 0.6mm Genuine Binzel - packet of 10

MB15 Contact Tip 0.6mm Genuine Binzel - packet of 10  1.6mm Aluminium Filler Rods (Grade 5356)

1.6mm Aluminium Filler Rods (Grade 5356)  Electrode Holder Screw Type - 600A

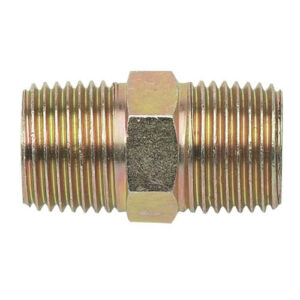

Electrode Holder Screw Type - 600A  Double Union 1/4" BSP

Double Union 1/4" BSP  Hi-Vis Two Tone Combat Trousers

Hi-Vis Two Tone Combat Trousers  CR39 Clear Lens - 5¼" x 4½" (133mm x 114mm) - Packet of 10

CR39 Clear Lens - 5¼" x 4½" (133mm x 114mm) - Packet of 10  3.2mm 2% Thoriated Tungsten (Packet of 10)

3.2mm 2% Thoriated Tungsten (Packet of 10)  EBP1100 1" Single Stage Electric Booster Pump

EBP1100 1" Single Stage Electric Booster Pump  BIZFLAME RAIN UNLINED - HI-VIS ANTISTATIC FR TROUSER - S780

BIZFLAME RAIN UNLINED - HI-VIS ANTISTATIC FR TROUSER - S780  PCL male fitting with 1/4 BSP Female inlet

PCL male fitting with 1/4 BSP Female inlet  MB15 Contact Tip 1.0mm Genuine Binzel - packet of 10

MB15 Contact Tip 1.0mm Genuine Binzel - packet of 10  1/2 BSP Male - Female PCL

1/2 BSP Male - Female PCL  R-Tech TIG Welder AC/DC 200Amp 240V with Accessory Kit

R-Tech TIG Welder AC/DC 200Amp 240V with Accessory Kit  1/4 BSP Male - Female PCL

1/4 BSP Male - Female PCL  R-Tech TIG Welder Digital AC/DC 260 Amp 240V with Accessory Kit

R-Tech TIG Welder Digital AC/DC 260 Amp 240V with Accessory Kit  Hose Connector (3/8" Nut X 3/8" Tail)

Hose Connector (3/8" Nut X 3/8" Tail)  1/4 BSP Standard Adaptor 5/16 Hose Tail

1/4 BSP Standard Adaptor 5/16 Hose Tail  CPE20A3 Ind. Self Priming Water Pump

CPE20A3 Ind. Self Priming Water Pump  SPE800 1

SPE800 1  Twin Air Flow Coupling

Twin Air Flow Coupling