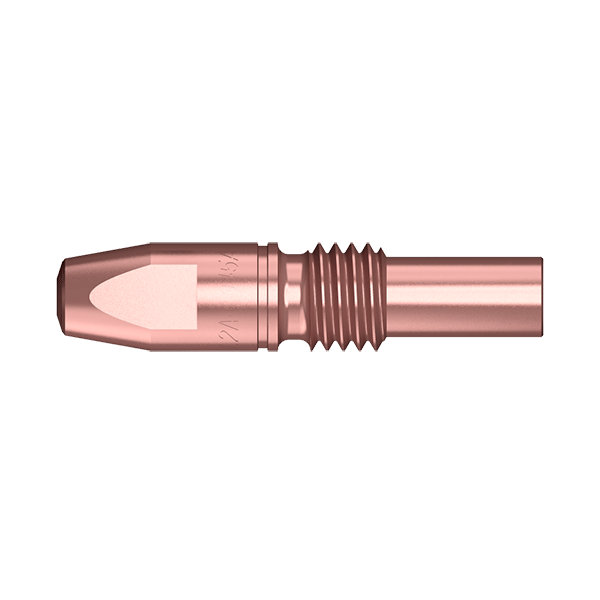

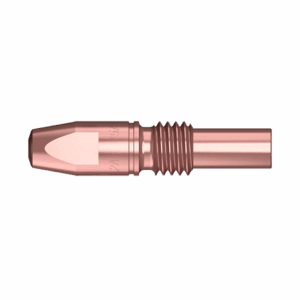

XP8 Contact Tip 0.035″ – 0.9mm (XP8-300A-450W) – Packet of 5

Ensure consistent MIG welding with the XP8 0.035″ contact tips. Durable, precise, and perfect for XP8-300A to 450W torches.

- Estimated Delivery : Up to 4 business days

Upgrade your MIG welding setup with the XP8 Contact Tip 0.035″ – 0.9mm (XP8-300A-450W) , designed for high-performance and precision. This professional-grade contact tip is crafted for consistent wire feeding, reduced spatter, and longer tip life — perfect for fabricators, metal workers, and industrial welders. Made specifically for use with XP8 MIG torches from 300A to 450W, it ensures a secure electrical connection, improving arc stability during extended welds. Whether you’re tackling stainless steel, mild steel, or alloy materials, these tips deliver consistent, clean results with 0.9mm wire. Each pack includes 5 contact tips, offering great value and reliable replacements for uninterrupted workflow. Trusted by professionals across Ireland, this XP8 tip ensures durability, precision, and efficiency in all welding environments. Compatible with industrial-grade operations and built for longevity, it’s a must-have for those demanding top-tier performance.

Key Features

High Precision Fit: Ensures stable arc and accurate wire feed.

Extended Tip Life: Built for durability in harsh welding environments.

Optimized for 0.9mm Wire: Perfect for precise, controlled welds.

Secure Electrical Contact: Delivers stable welding performance.

Multi-Torch Compatibility: For XP8 300A to 450W MIG torches.

Detailed Specifications

Product Type: Contact Tip

Wire Size: 0.035″ / 0.9mm

Compatible Torch Range: XP8 300A, 320W, 350A, 400A, 450W

Thread Type: M10

Material: High-conductivity copper alloy

Pack Size: 5 tips per packet

Application: MIG Welding for steel, stainless, alloy

Product Benefits and Uses

Ideal for Professional Fabricators: Designed for industrial-grade performance.

Reduces Downtime: Long-lasting contact tip means fewer replacements.

Improves Weld Quality: Provides better arc control and smoother finish.

Perfect for Consistent Production Runs: Maintains high-quality welds over time.

Supports Various Materials: Works on mild steel, stainless, and more.