“How to Choose Aluminum Welding Shielding Gas”The selection of a suitable gas for shielding will be the conclusive element in the quality of your aluminum welding. A wrong combination can produce weak joints, porosity, or uneven beads, and all this combined can lead to poor quality of the welding. Smooth operation, clear finishes, and the same strength will be the result of choosing the right gas for MIG welding, no matter if you are using MIG or any other process. Let us walk you through the process of selecting the right gas for the job step by step.

Step-by-Step Guide to Choosing the Right Shielding Gas for Aluminium

The selection of the right shielding gas for MIG welding aluminum can be the determining factor in the weld quality. Gas mixture and the thickness of the material are among the details that matter. To get strong, flawless aluminum welds every time, just follow these expert steps.

1. Identify Your Welding Process and Material Thickness

Prior to any gas selection, it is important to regulate the welding method and the thickness of the aluminum to be welded. If MIG welding is the process, seek only gas for MIG welding. The gas flow with the thinner aluminum will be very smooth as the heat input will be low. On the other hand, the thicker sections will require high penetration and temperature control.

2. Choose Pure Argon as the Base Shielding Gas

For the majority of aluminum MIG welding applications, pure Argon (100%) is the best option to start with. This gas that does not react creates a stable arc, excellent cleaning action, and an easy-to-control weld pool. Pure Argon also suits thinner aluminum materials well and gives clean, bright welds besides lowering oxidation and spatter risks.

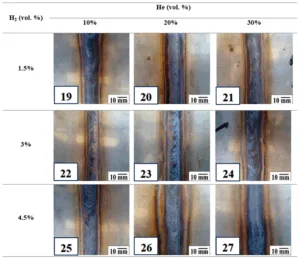

3. Consider Adding Helium for Thicker Aluminum or Faster Speed

If high-speed production work or thick aluminum welding is the case then adding helium to your shielding gas will be a great help for performance. Helium raises the arc heat and penetration thus it is preferred for deeper welds and faster travel speeds. Mixtures like 75% Argon and 25% Helium are very common and they provide a perfect compromise between cost and weld quality.

4. Avoid Reactive Gas Additives and CO₂ Mixtures

During the welding of aluminum, never employ CO₂, oxygen, or any other reactive gases, mainly in MIG usage, for instance. These gases create pores, lead to oxidation, and form weak fusion lines, all of which affect the quality of the weld negatively. It is also worth noting that the shielding gas used in MIG welding on aluminum is to be exclusively inert Argon or Argon-Helium mixtures so as to avoid any atmospheric contamination of the weld.

5. Match the Gas to Your Wire, Transfer Mode, and Position

The performance of shielding gas is influenced by different wires, transfer modes, and welding positions. Higher helium content is beneficial in spray transfer welding, on the other hand, short-circuit transfer can work better with pure Argon. Always match your gas selection with equipment setup and welding position to get the smoothest and most consistent results.

6. Set the Correct Gas Flow and Check for Leaks

Even the best shielding gas for MIG won’t help if your flow rate or equipment setup is incorrect. The usage of proper gas flow is very important when doing welding so that the weld pool will be completely covered by the gas. Besides, make sure that your regulators, hoses, and torches do not have any leaks. A flow that is steady and constant helps cleaner welds and prevents atmospheric contamination that might occur and lead to discoloration or weak joints.

Pro Tips and Common Mistakes

Shielding gas mastery is not just about picking the right blend but also about proper application. Many welders unknowingly make minor mistakes that spoil even the best weld setup. Here are the ways to secure those mistakes and thus increase the quality of your aluminum MIG welding.

1. Use Dedicated Cylinders for Aluminum

In welding aluminum, maintain a separate Argon cylinder to secure against cross-contamination that may result from welding other metals. The use of dedicated instruments aids in the retention of gas cleaness and the prevention of contamination that might weaken your welds over time.

2. Experiment with Argon-Helium Blends for Deep Penetration

When working with thick aluminum or structural welds, consider trying out Argon-Helium mixes. The involvement of helium in welding increases arc voltage and penetration which results in awesomely strong joints and fast welds without any quality issues.

3. Always Clean the Aluminum Surface Thoroughly

Surface cleaning is as essential as the right gas. Aluminum oxide and aluminum have different melting points; the first one is higher than the latter, so, it must be completely absorbed before welding. Even perfect shielding gas can’t prevent issues caused by surface contamination.

4. Use Post-Flow Shielding for Better Finish

A short post-flow of shielding gas should be maintained after welding to cool down the molten pool. One of the advantages of the trailing gas method is that it prevents oxidation and provides a smoother and shinier weld bead finish.

5. Monitor Your Arc Stability and Weld Appearance

Stable arc, uniform bead, and consistent sound are excellent indicators of the proper shielding gas choice. A flickering of the arc could be a sign that the gas flow has been disrupted. Be vigilante with the weld’s behavior and make minor accommodations if essentials.

Conclusion

The selection of a suitable shielding gas for MIG welding aluminum will truly enhance your experience and make your welding operations clean, strong, and trustworthy. If one is a novice, they will require only Pure Argon; upon that, if more heat or deep penetration is desired, Argon-Helium mixtures can be utilized. Do not use reactive gases and ensure the correct setup of the equipment, adequate gas flow, and proper surface preparation. Your aluminum MIG welds will be as good as new and last longer if you are meticulous in these areas.

FAQ’s

Q1. What is the best shielding gas that is used for MIG welding aluminum?

The best option is purely Argon. It assures outstanding arc stability and clean welds along with bright finishes, being particularly favorable for thin or medium aluminum sections.

Q2. If yes, can Argon and Helium together be used for MIG welding aluminum?

Without a doubt, a combination of Argon and Helium not only raises the penetration but also tthe ravel speed, hence it is ideal for wide aluminum material or fast production settings.

Q3. Why is it advantageous to avoid CO₂ or oxygen-based gases during aluminum welding?

CO₂ and O are classified as reactive gases that result in the creation of pores and aluminum oxidation in welding, thus causing weak joints and poor surface finish.

Q4. What is the gas flow rate that is considered to be the best for the welding of aluminum using the MIG technique?

A constant flow of approximately 20-30 CFH is the most common option, but it will vary depending on the diameter of the nozzle, draft conditions, and the specific equipment being used.

Q5. Does the welding position affect my shielding gas choice?

Definitely. The welding positions, like overhead or vertical, will probably require you to tweak your gas mix or flow rate to ensure proper coverage and penetration.